Cut and sew items are usually custom one-offs or prototypes fabricated from the thread on up.

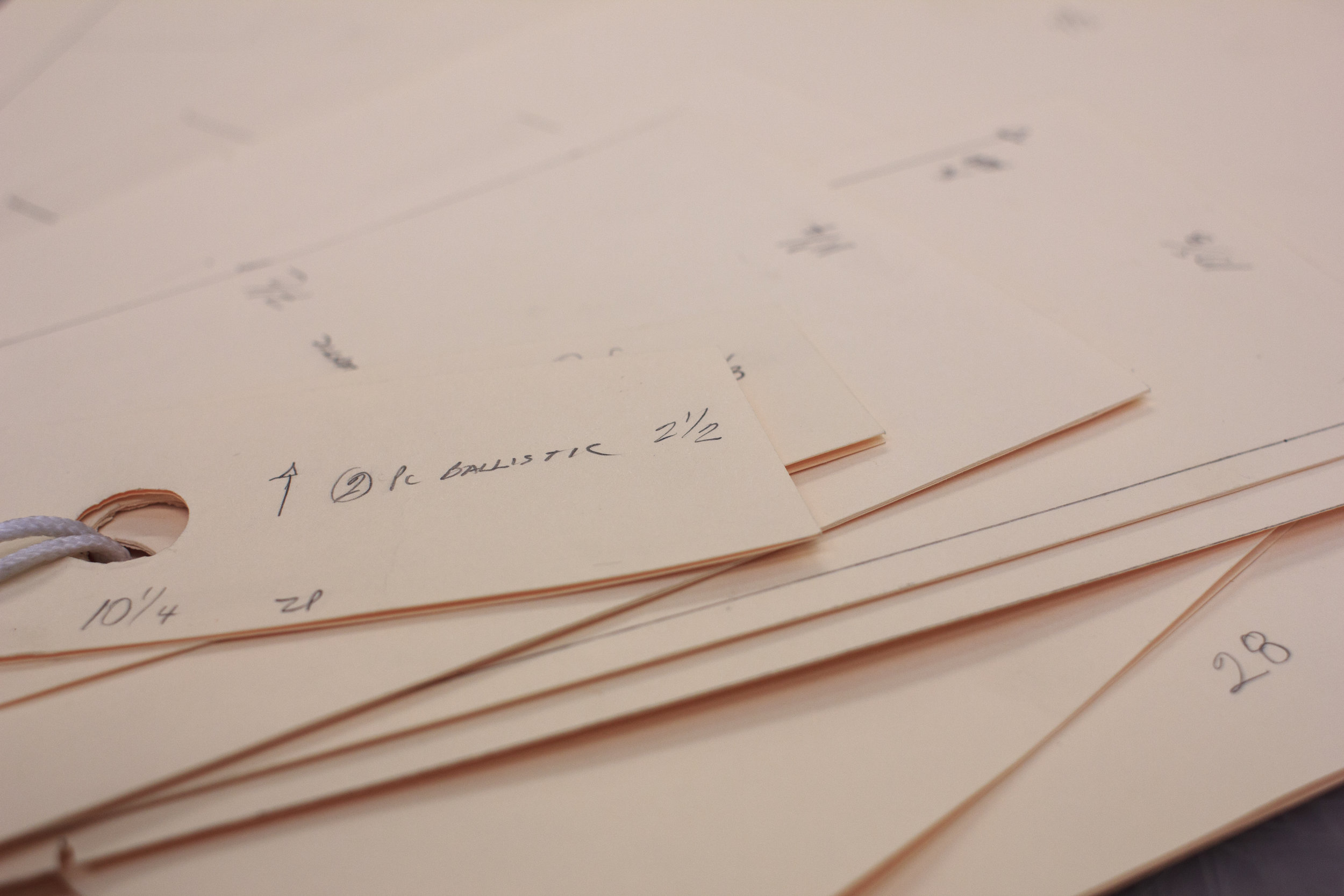

Transforming such a unique item into a product ready for mass production involves careful planning, which becomes manifest in the form of a Cutting Ticket.

So what is a

Cutting Ticket exactly?

Conceptually speaking: Cutting Tickets make up the entire Cut Order of a project, and are to contract sewers what the specific blueprint of a room is to an architect building a house.

To put it less poetically: Cutting Tickets are the plans and specifications for cutting an order.

This includes everything from the contractor information, to a list of the patterns, styles, quantities, fabrics, layers, hardware, and colors that need to be cut. Cutting Tickets can range from simple to complex, and remain iterative as a working document. For example, if a fabric is damaged or stained and flagged by Quality Assurance then it is removed from the order and the Cutting Ticket is amended.

CUTTING TICKETS

Core Elements &

What You Need To Know!

While the specifications and intricacies of Cutting Tickets are always different, there are a few core elements that are necessary:

1. Cutter's Must

2. Cut Order Plan

3. Markers & Plates

4. Bill Of Materials

CUTTER'S MUST

A Cutter’s Must is an itemized listing of the pattern pieces and components in a Cutting Ticket.

CUT ORDER PLAN

Also known as a Purchase Order, a Cut Order Plan has specifications for the cutting of a production run and accounts for every cut with its own number. In the event there is a manufacturing defect in an order, a Quality Control inspector can use a cut number found in the Cut Order Plan to track mistake to a particular production lot and determine with granular accuracy where and when the mistake or pattern change occurred.

MARKERS & PLATES

Markers are used as a template to trace patterns on to pieces that need to be cut to a given shape. Likewise, plates help automate the cutting process when there are larger order quantities and are custom made per order. To streamline the process CustomFab USA has in-house tooling to make specialized plates for our customers which we protect as their proprietary information.

BILL OF MATERIALS

Everything from the amount fabric, to hardware, and even thread should be accounted for in the Bill Of Materials (BOM) when planning a product for mass production. Each Cutting Ticket has is own BOM included, which can help with calculations to optimize material use. For instance let’s say you only planned on cutting 1,000 units in the Cut Order Plan, but your BOM shows you’ll have enough materials left over for an extra 50 units. In this scenario it might pay to purchase additional hardware and supplies to make a some extra products at a reduced cost.

CONTRACT SEWING GURU ARCHIVE

- American Manufacturing

- Announcements

- Business Efficiency

- Business Strategy

- Compliance

- Contract Sewing

- Contract Sewing History

- Cut and Sew Technology

- Environmental Impact

- Hardware

- Industrial Sewing

- Industry Tips

- Industry Updates

- LEAN

- Made in the USA

- Manufacturing

- Manufacturing Interview

- Manufacturing Partnership

- Medical

- Military Gear

- Patriotic

- Policy & Compliance

- Quality Control

- Reshoring

- Sewing Contractor Trends

- Sewing News

- Skilled Sewing Workforce

- Sporting Goods

- Supply Chain Management

- Sustainable Manufacturing

- Tax Incentives

- Threads of Transformation

- White Label Benefits

- contract sewing tips